Acme Industries, Inc.

Where Small Business responsiveness meets large Business Capabilities

Capabilities

Machinable Materials

We are capable of machining a wide array of materials including Aluminium alloys, steels including Titanium and even types of machinable plastics.

Machining Centers

Here is a list of the machines we Currently have

- (3) OKK VM5 Vertical Machining Centers 20" x 40" x 20" travel

- (1) OKK VM7 CNC Vertical Machining Center 60" x 30" x 24" travel

- (1) Makino A82 CNC Horizontal Machining Center 43.3" x 32.3" x 40.1" travel

- (1) OKK HP-500S CNC Horizontal Machining Center, 8 Pallet 25" x 24' x 28' Travel

- (1) OKK HM 50 CNC Horizontal Machining Center 24" x 22" x 22" travel

- (1) OKK MCV860 CNC Vertical Machining Center 80" x 33" x 28 travel

- (1) OKK PG 8 CNC Vertical Machining Center 20 x 16 x 16 travel

Software

Acme Industries uses the latest software to help ensure the fastest production times. We are capable of viewing customer models on the latest version of Dassault systems Catia. Our workstations also have a complete CAD/CAM/CAI system including the latest version of Mastercam and PCMIS. JobBOSS Shop Management Software is also used to ensure parts are managed efficiently.

Inspection

Climate Controlled Quality Department AS9100 and ISO 9001:2008 Certified, ITAR Registered

Inspection equipment list

- Brown & Sharpe Global Peformance DCC CMM 36" x 80" x 20" Travel

- Brown & Sharpe MicroXcel CMM 40" x 29" x 20" Travel

- Wilson Rockwell Hardness Tester

- Magnaflux Conductivity Tester

- Federal Air Gauges

- Gage Trak Calibraion Managment Software

Assembly

Our Assembly Department is fully equipped to handle various assembly ops including Riveting, Sealing, Press fitting and much more

Riveting

We are equipped with two US Air Tool rivet guns one bench-top and one hand-held allowing us to handle a variety of riveting tasks. Our hand held model has a throat depth of 1-1/2" and the Bench-top model has a reach of 10" and a gap of 3-1/2".

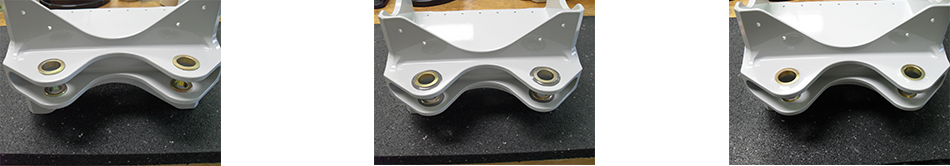

Sealing

Many Aerospace part require some form of sealant to protect components from corrosion. Shown below is a example of a filet seal around bushings that were recently installed. after the sealant cures a coat of primer and paint is applied to complete the part.

Threaded Inserts

Helicoils, Pemnuts and key inserts are just a few of the types of threaded inserts Acme has the capabilities of installing